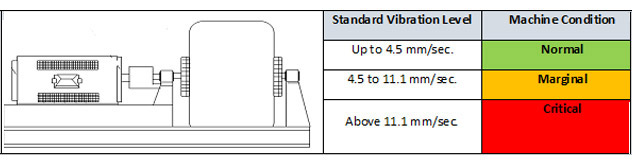

In-situ Dynamic balancing is one of the widely used expert service in industry. In-situ dynamic balancing is carried out in the site without dismantling Fan/Blower from its installation. This process minimise down time of Fan and also saves cost of transportation, time etc

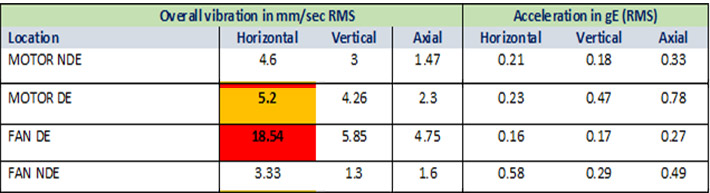

Observation: Casing Vibration Measurements at Load condition.

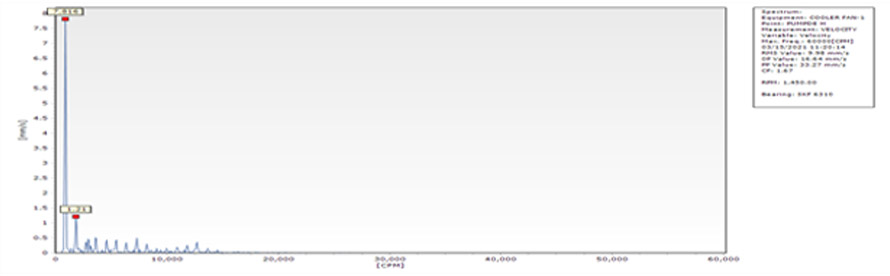

OVERALL VIBRATION READINGS: The maximum overall vibration amplitude recorded was 5.20 mm/sec RMS in Horizontal direction at MOTOR DE bearing; 18.54 mm/sec RMS in Horizontal direction at FAN DE bearing.

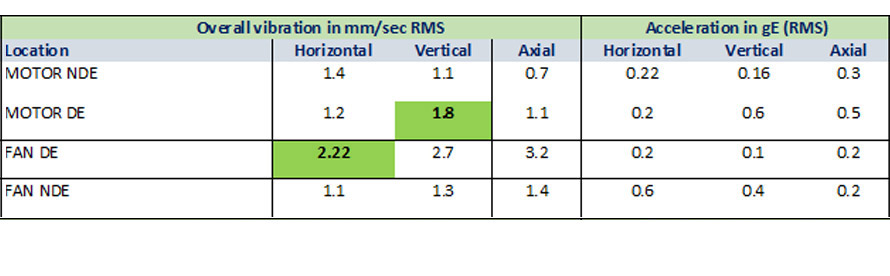

OVERALL VIBRATION READINGS: The maximum overall vibration amplitude recorded was 1.8 mm/sec RMS in Horizontal direction at MOTOR NDE bearing; 2.22 mm/sec RMS in Horizontal direction at FAN DE bearing.