Manufacturing any product requires producers to focus on minimizing waste, reducing costs, continually increasing product quality and maximizing overall plant efficiency, moisture control can play a large role in maintaining the efficiency of the plant. Creating the need to evaluate and implement lean manufacturing practices to identify the key areas in which the manufacturing process is not operating at its peak ability. MoistTech produced the IR3000C sensor to precisely measure moisture, coat weight, thickness and temperature in converting applications such as paper, films, foils, composite board, hot melts, glues, recycled paper, wax and vinyl coating, resin and many more.

Thoroughly evaluating methods of reducing wasted product, efforts, time and energy will provide the needed efficiency to increase plant productions. Proper moisture measurement and control can play a large role in the overall process and quality of the product, implementing a moisture management system is low cost and instant ROI.

Often efficiency in the converting process is affected by variations in coat weight, inefficient moisture control, thickness and/or temperature issues. Moisture and thickness play a large role in the final product quality and use.

Precise moisture levels in paper, pulp, tissue, corrugated line and other converting products is a crucial component to the manufacturing process. Out of tolerance moisture levels create wasted product, increased energy usage, downtime and more. Improved product quality and productivity in processing lines through proper moisture control, creating substantial cost savings.

Maintaining the ideal thickness or coat weight in the production line can mean the difference between a quality product you provide your customers or wasted effort and material. Many basic properties of paper are greatly affected by its moisture content. Its dimensions, flatness, conductivity, strength and fold are among the more significant properties influenced by its moisture content.

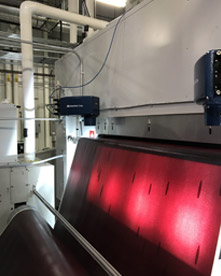

The IR3000C series sensor is an on-line, instant, non-contact moisture reading system that is can be installed in many configurations using the bracket on the back or top of the sensor enclosure. Most typical installations are mounted 4 – 16” (inches) from the product flow to be precisely measured. Changes in product flow can be compensated for by using our filtering, damping and averaging.

Out of tolerance moisture levels create wasted product, increased energy usage, downtime and increased start up times. Processing lines can see improved product quality and increased productivity with proper moisture monitoring, creating substantial cost savings. Maintaining the ideal moisture, thickness or coat weight in the production line can mean the difference between a quality product to provide your customers or wasted effort and material. Many basic properties of paper are greatly affected by its moisture content: paper dimensions, flatness, conductivity, strength and fold are among the more significant properties influenced by moisture control.

Thousands of MoistTech analyzers are installed not only for the measurement of moisture, but also for other applications such as measuring and controlling: coating thickness, resin content, glue and plastic film thickness and many other constituents – all with one sensor!

The online moisture transmitter can be in a stand alone or multi-sensor configuration.