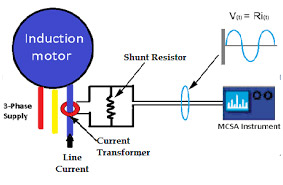

MCSA program detects motor faults such as broken/cracked bars as well as problems with the high resistance joints on any AC induction motor. Motor Current Signature Analysis (Here after MCSA) technology was the detection of rotor bar faults. Rotor bars are difficult to assess using traditional test methods, including vibration analysis.

Motor current analysis is a valuable additional technology to apply as part of a complete Machinery Health Management program. Motor current analysis provides a conclusive indication of broken rotor bars by identifying the "slip times number of poles" sidebands around line frequency (50 Hz) and comparing the sideband amplitude to the amplitude of the line frequency peak. If the sideband amplitude rises to within 45 dB of the line frequency peak, a problem is indicated, 35 dB indicates severe damage.