Vibration analysis is a process that monitors the levels and patterns of vibration signals within a component, machinery, or structure, to detect abnormal vibration events and to evaluate the overall condition of the test object.

Our qualified and experience engineers can help you pin-point machine defects or fault conditions, we have expertise in diagnostics of motors, pumps, fans, gearboxes, bearings, turbines, generators, and many other machineries.

Vibration analysis can identify following problems,

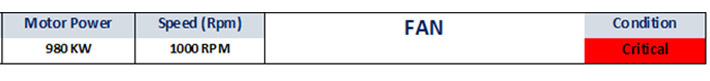

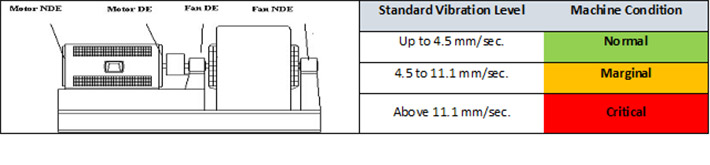

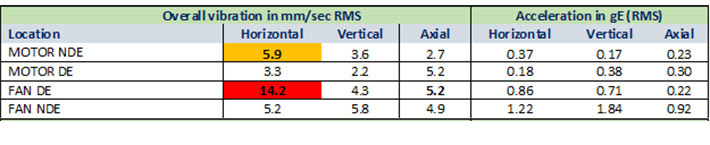

Observation: Casing Vibration Measurements at Load condition

OVERALL VIBRATION READINGS: The maximum overall vibration amplitude recorded was 5.9 mm/sec RMS in Horizontal direction at MOTOR NDE bearing; 14.20 mm/sec RMS in Horizontal direction at FAN DE bearing.

INTERPRETATION: Since all the amplitudes are not within limits and this is “Critical”.

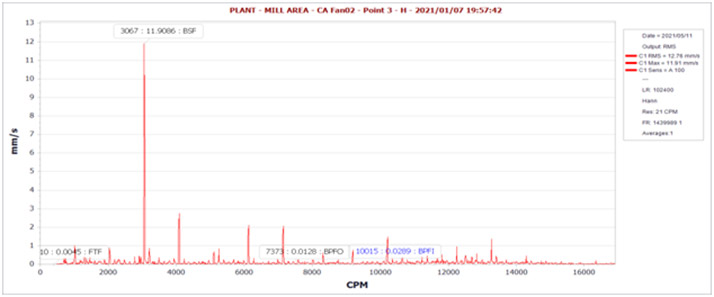

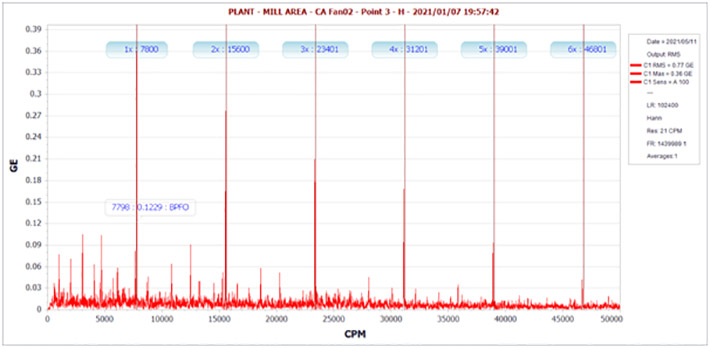

OBSERVATION: Fan vibration spectrum generating Ball Pass Outer race and Ball spin frequencies which are indicating the symptoms of bearing inaccuracies.

RECOMMENDATIONS: Inspect the Fan both bearings for any inaccuracies related to Ball Spin frequency and Ball Pass Outer Race frequency.